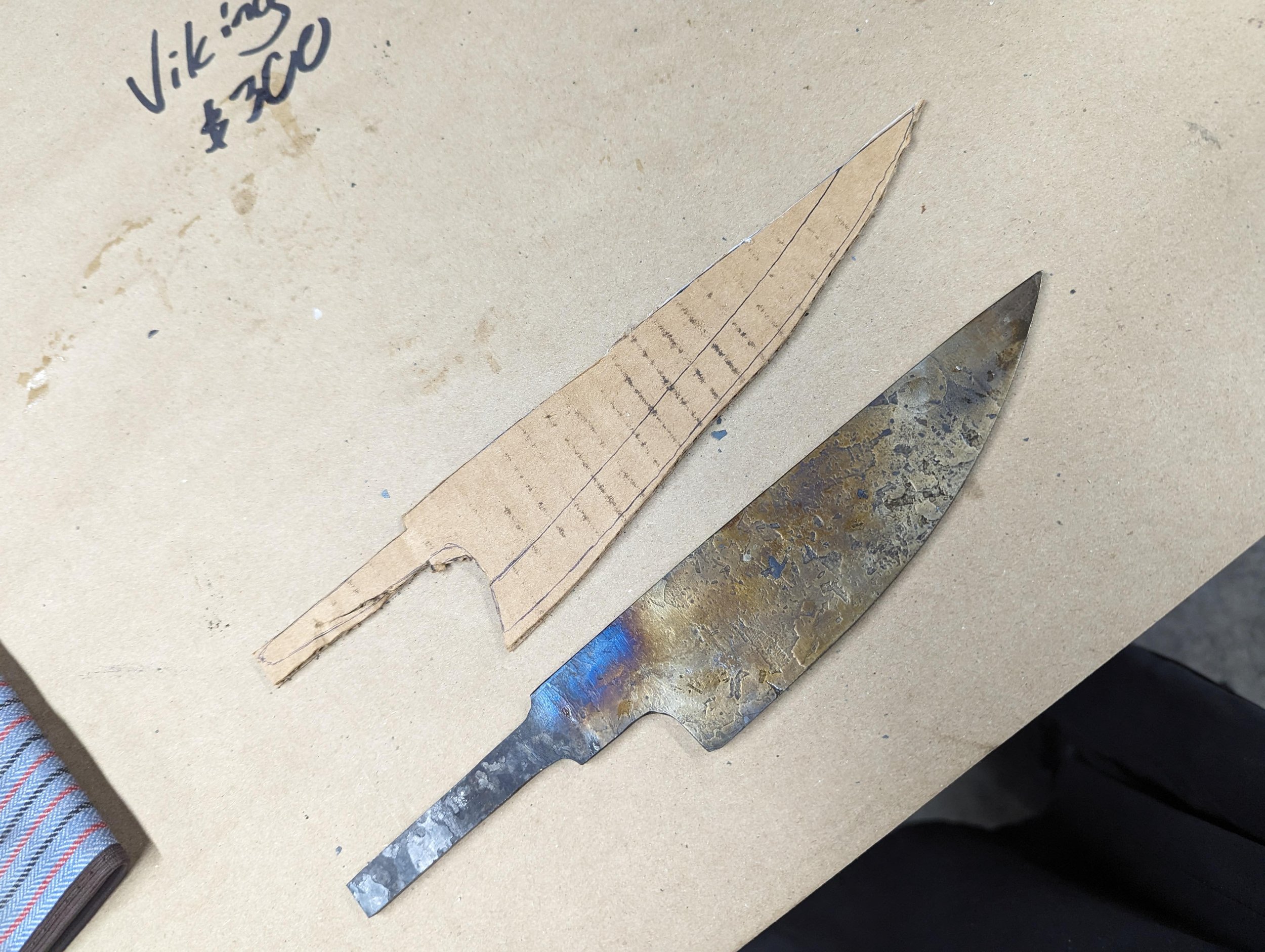

So what do you do if you’re an up-and-coming bladesmith but don’t have a forge let alone know if you like the idea of forging? You take a class and forge with someone else’s propane and tools. So I went to a place called the Drunken Smithy because your swords aren’t the only things that deserve to be hammered.

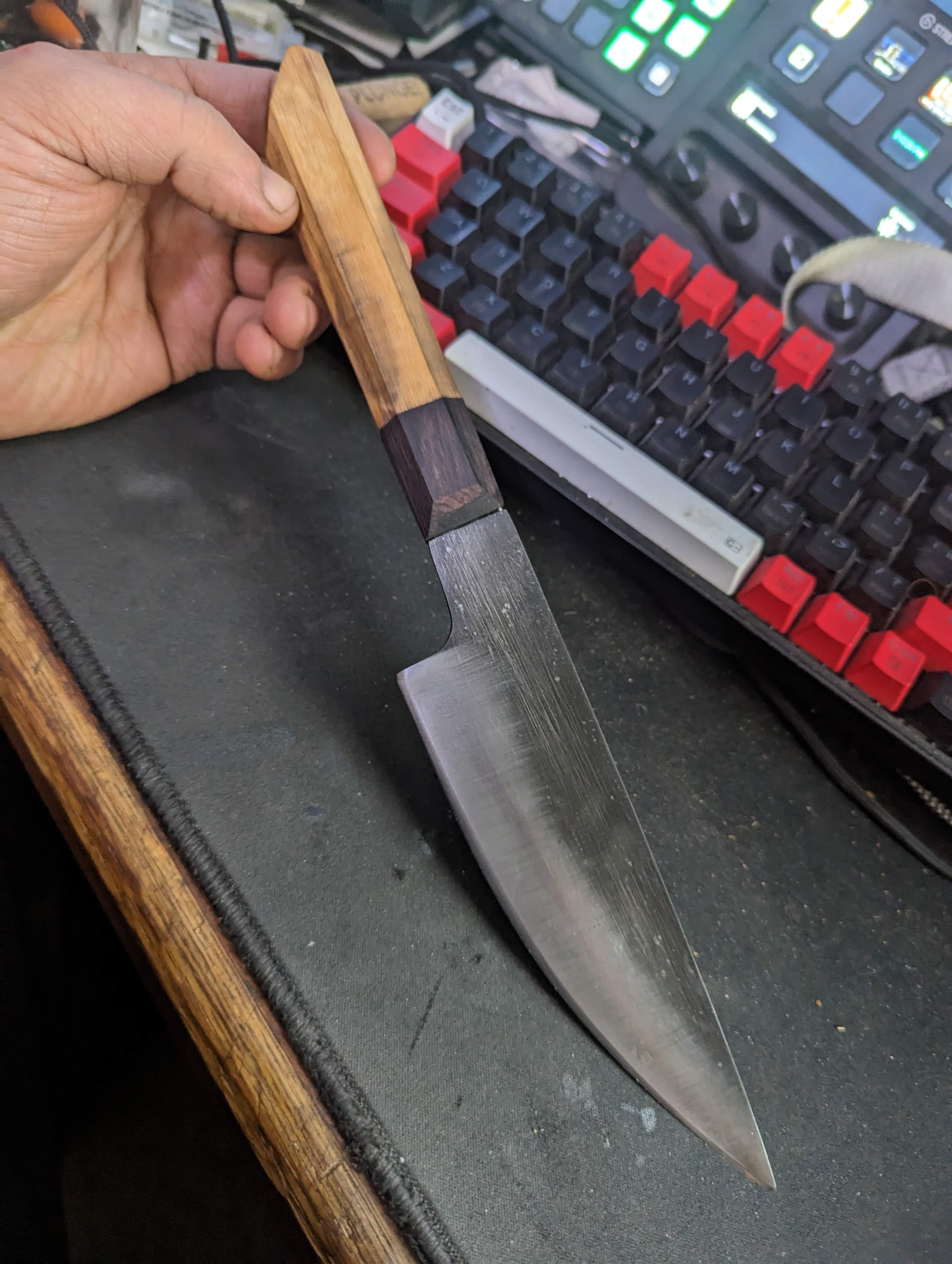

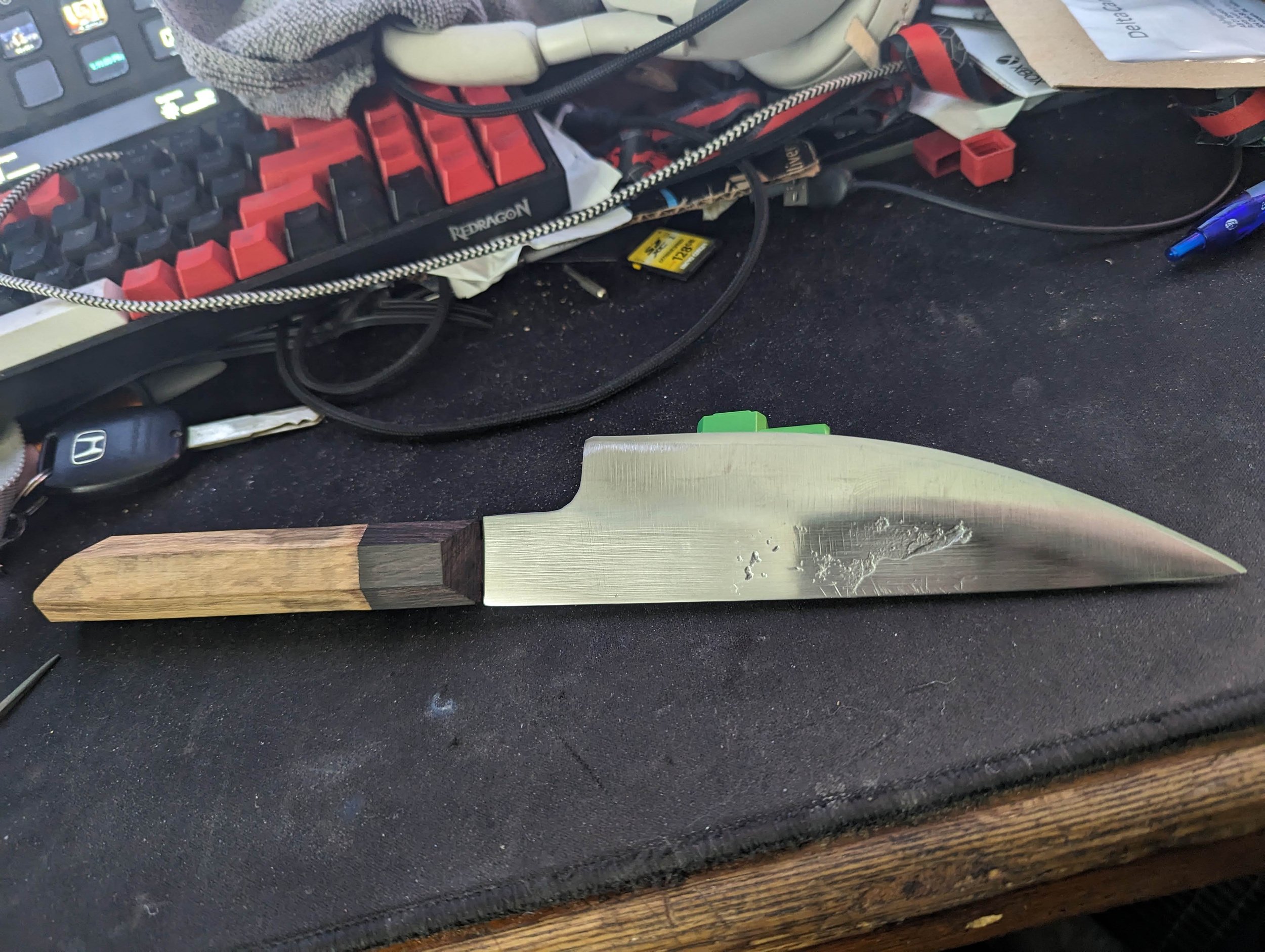

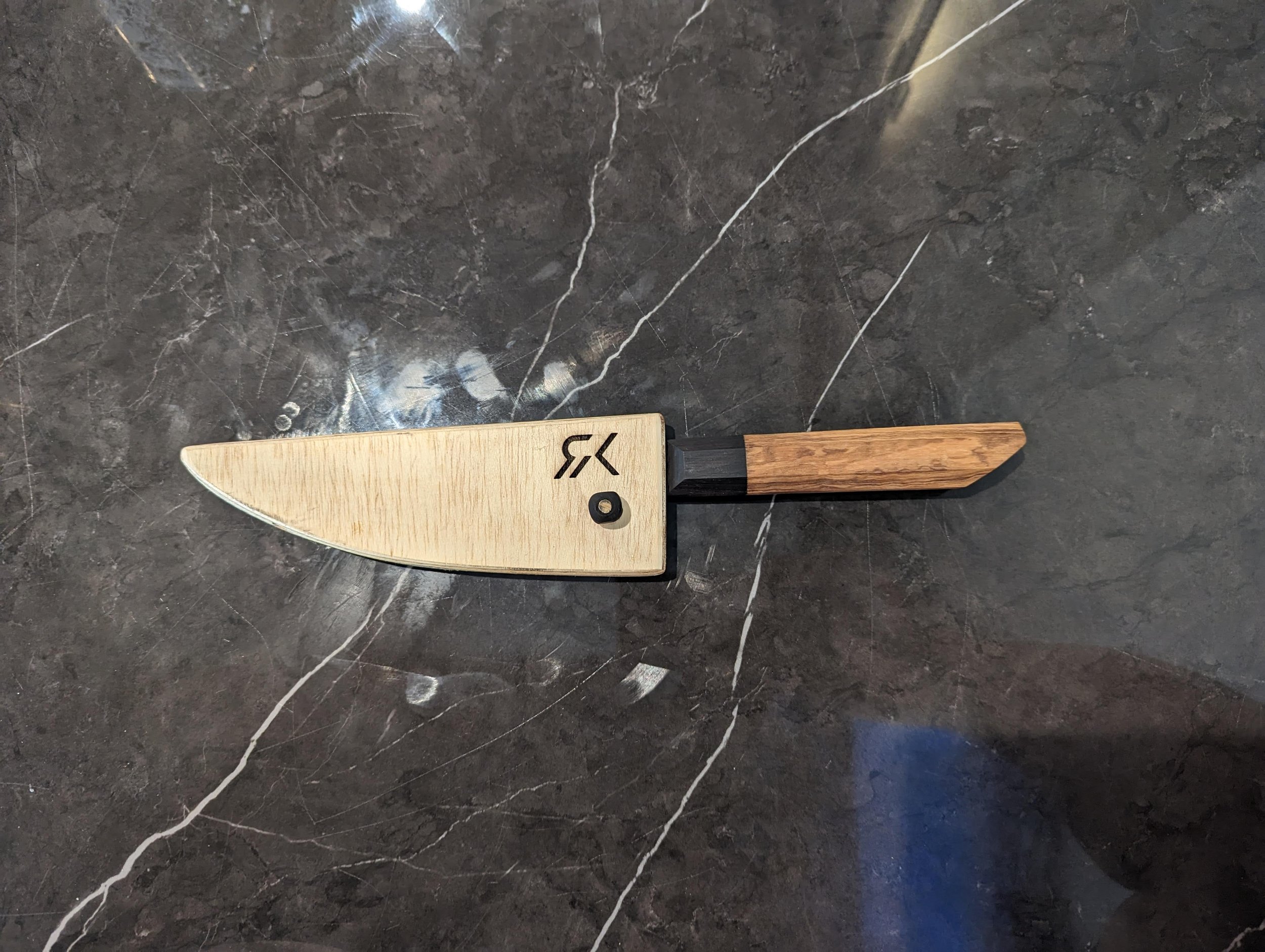

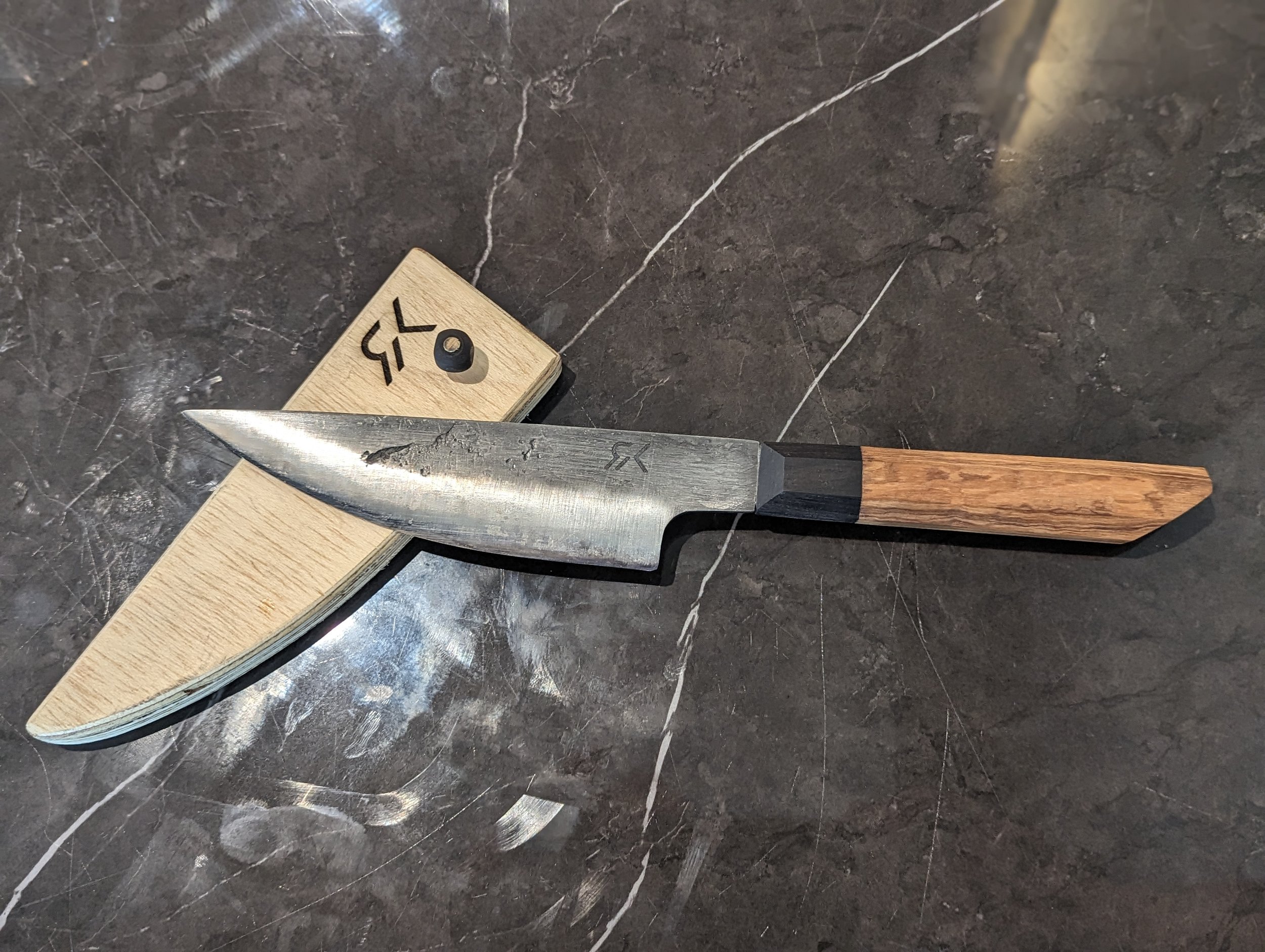

I digress this is the result of what I did during the class. I forged a billet of 1065 High Carbon steel into a shape and I did make some mistakes but you’ll see in the pictures I got close to what I wanted. The class was great because I wanted to do certain things that the class wasn’t designed for like I wanted to flat grind my edges but they were set up for hollow grinding. After a quick conversation and some questions to verify I wasn’t going to leave disappointed. they let me take the knife home hardened and tempered without an edge (since this is how I make most of my knives currently) Once I got home I started the process and I refined the shape into a lovely Honesuke-esk profile and refined the thickness and shape. I left it a bit thicker than I usually do because I wanted to leave some of the imperfections to highlight the hand-forged nature. I doubled down by leaving some of the sanding marks and grind lines visible. For the handle, I left it more of a rustic rough finish to compliment the rest of the design.

6.25-inch Honesuke style knife - 174g (225g with Saya)

3.5mm spine thickness flat ground with a micro-bevel to strengthen the edge.

Steel is 1065 High Carbon - 58 +/- 2 HRC

The handle is made of olive wood and ebony. Rough sanded to 220 grit to match the look of the rustic blade. The blade was etched in Ferric chloride and then instant coffee to stain the steel, with a scotch-brite finish applied to the primary bevel for a nice contrast.

I’m very pleased with how this turned out.